Table of Contents

Cargo Lift Size and Relative knowleges

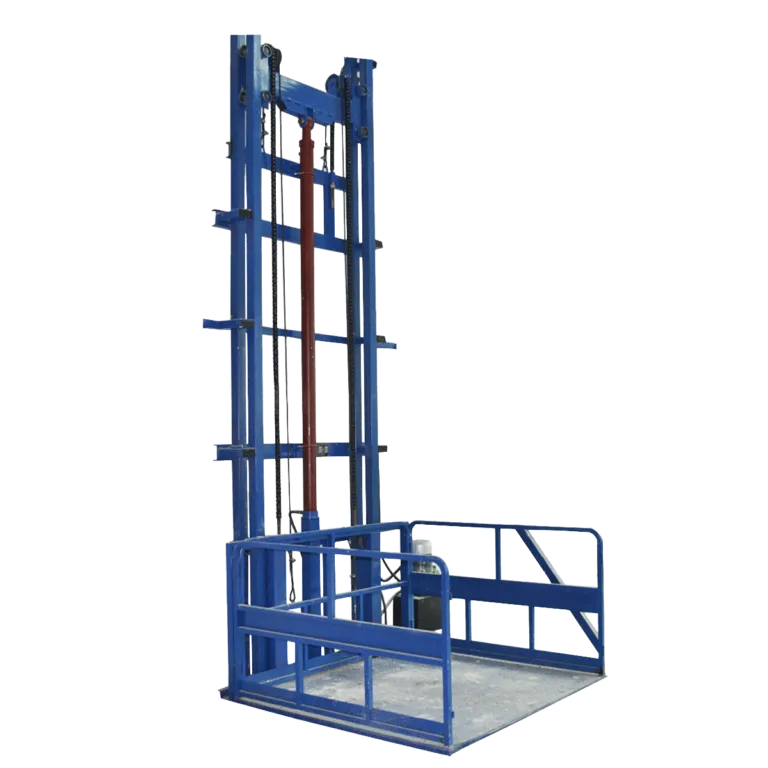

Our common guide rail hydraulic elevators used for vertical transportation of goods between floors are generally a non-standard customized freight elevator product. As long as your use environment is suitable for the installation of guide rail hydraulic elevators, we will leave the follow-up work to us That’s it. After receiving your consultation, we will first design a pit map of the installation location for you for free. The foundation needs to be made by the user. We can provide you with free remote guidance. The custom process for guide rail hydraulic lifts with a lift of 2 meters to 30 meters and a load of 0.5 to 100 tons are similar. MORN Machinery is very skilled in this area.

Conditions that need to be understood when customizing guide rail hydraulic lifts:

- We will provide you with instructions for making the equipment installation foundation according to the size of the user’s installation space. The length, width and depth of the pit are determined by the external dimensions of the equipment. The bottom surface of the pit should be poured with concrete when pouring, and it is indicated in the drawing Pre-embedded parts should be made at the position of, for the link between the equipment and the foundation, and the pit should be square and not deviated;

- When the size of the installation space is determined, the size of the working platform of the guide rail hydraulic lift is a part smaller than the installation space, because the rails are installed on the left and right sides, and a suitable margin should be left for the vertical operation of the equipment;

- The elevation and load capacity of the equipment are not limited by the use environment, but after we design the size and load capacity you need for you, you should not overload it and deal with any problems in time;

- The height of the rail type freight elevator is generally only 30 cm, and it can be installed without digging too deep foundation pit;

- If the guide rail hydraulic lift is used in the chemical or pharmaceutical industry, special protection settings such as explosion-proof and dust-proof are required;

- Before setting, be sure to measure the accurate lifting height of the equipment, and measure the volume and weight of the one-time shipment.

Let’s say that after the contract is signed and the product is completed, we will ship it through logistics. After the user receives your customized guide rail hydraulic lift, check whether the accessories are complete and whether the surface of the equipment is scratched. Box acceptance record

- First, clarify the type of products you need: For example, you must first determine whether your lifting platform is used for lifting aerial workers or for cargo. Only when this point is clear, we can have a direction to choose.

- Determine product lifting parameters: You must clarify the required lifting height, deadweight tonnage, table size and other parameters, so that you can inform the elevator manufacturer of this requirement and let the MORN lifting platform give reasonable suggestions and products.

- Compare elevator manufacturers and products, choose the right hydraulic lifting platform, and choose Chengdu Licheng Hydraulic Machinery Co., Ltd., a manufacturing enterprise specializing in the R&D, production and sales of hydraulic elevators, lifting platforms, and lifting freight elevators.

Knowing so much, in a word, you have to shop around, determine the final product you need, and choose the appropriate elevator manufacturer to purchase. It is recommended that users choose the appropriate elevator platform when ordering to meet their daily needs.