When buying a lift platform, please consider the following factors;

-Quality of a lift platform

-Lift working frequency

– Scope of use and rated capacity

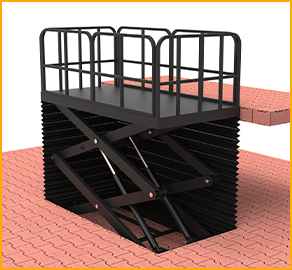

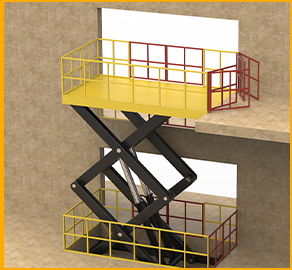

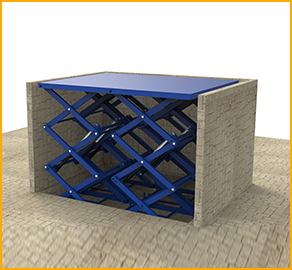

Usually, lifts have several models such as stationary, scissor structure, mobile lift, hydraulic lift, vertical lift, boom lift. You need to choose the most suitable model that will cater to your needs, with a wide range of application and is multi-functional machine

Quality of Scissor lifts

Some lift manufacturers have a bad habit of producing low-quality lifts in order to save the costs of manufacturing. The service life and safety of such lifts will be bad. When you decide to purchase a scissor lift, go for a good quality even if it will cost you more so that it can be durable.

After-sales service

Market research is paramount in order to know more about a lift manufacturer. Ensure you check the supplier’s credibility, if after-sales service is good and if there are contracts.

When selecting lift suppliers, do not only check their reputation but also pay attention to their after-sales service.

Confirm if the product’s features are complete, performance is good, complete security configurations are ok, prices are reasonable and after-sale service is good.

Finally, when the lift that you ordered arrives, open the box and do full inspections. Check its technical data, brochures, certificate documents, and accessories. Check whether the features are consistent with the list in the annex.

Also, let professional technicians check the equipment and accessories for damage and defects. Fill the document of acceptance to avoid cases of returns which leads to unnecessary disputes.

Contact us before you buy a lift, our lift engineer team is capable of giving you a perfect lift solution.