Hydraulic Cargo Lift

Cargo Lift, Goods Lift, Freight Elevator for Warehouse and Mezzanine

Cargo Lift

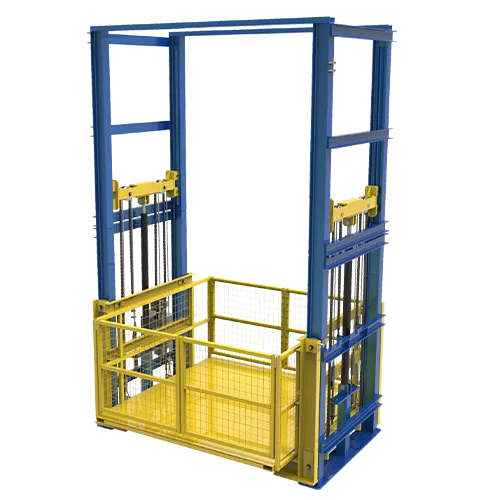

A cargo lift, also known as a goods elevator or freight elevator, is essential for transporting goods within buildings or structures, particularly in commercial and industrial settings like warehouses, factories, and distribution centers. Operable either manually or automatically, these lifts utilize various power sources such as electricity or hydraulic systems and are equipped with safety features like sensors, emergency stop buttons, and safety gates to ensure secure transportation of goods.

As an economical solution for low-floor goods transportation, cargo lifts offer versatility to accommodate diverse cargo handling requirements. With over 20 years of expertise, we provide an array of models and optional configurations tailored to your specific needs. Our standard cargo lifts boast a capacity of up to 13,228lbs and a lifting height of 33ft. Moreover, customization options for cargo lift capacity, lifting height, and lift platform are available to precisely align with your requirements.

Partner with us, and our dedicated team will craft a highly efficient lift equipment solution tailored to your unique needs. Take the first step toward enhancing your material handling capabilities by requesting a free 3D design consultation today.

Request a free 3D design now.

Features:

- Strict quality assurance and CE certification;

- Custom design for your lifting requirement;

- Rugged leaf chain and wire rope ensure stable running;

- PLC control system provides safe and stable operation;

- Smooth and efficient raising & lowering of the platform;

- Free 3D design based on your installation site;

- 7x24h technical support and after-sales service;

Cargo Lifts For Sale

Discover MORN’s versatile cargo lift range, including the Two Post, Four Post, and Fully Caged models, engineered to excel in various installation scenarios and material handling tasks. With prices ranging from USD3,500 to USD20,000, depending on your chosen specifications and optional enhancements, our solutions offer unparalleled adaptability and efficiency. Our dedicated team is committed to delivering superior-quality cargo lift equipment tailored precisely to your requirements, ensuring maximum value for your investment. Explore our offerings today and elevate your material handling capabilities with MORN.

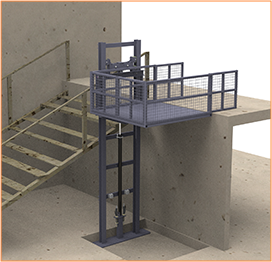

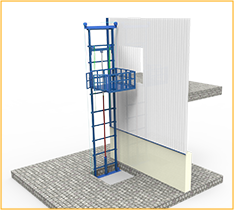

Two-post cargo lift, also called wall mounted goods lift, is suitable for handling goods in small space with smaller capacity. It is widely used in indoor or outdoor places of the buildings

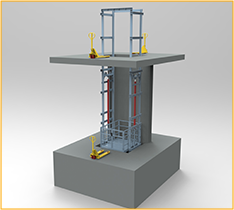

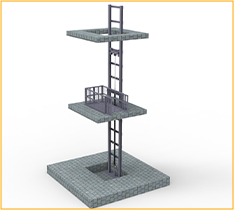

Four post cargo lift is widely used in indoor or outdoor workplaces of the buildings and warehouses, lifting goods or pallets among different vertical floors.

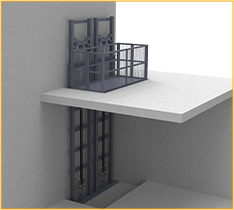

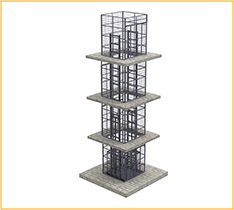

Fully caged cargo lift is covered by steel mesh for safe loading. This kind of goods lift is well suited for multi-level applications with goods fully enclosed in a protective mesh shaft.

After-Sales Service

Comprehensive Support:

The after-sales service for cargo lifts includes a wide range of support options to cater to the needs of customers. This may include technical assistance, troubleshooting, maintenance, and repair services.

Prompt Response:

A key aspect of after-sales service is providing a quick and efficient response to customer inquiries or complaints. MORN LIFT service team will be readily available to address any concerns and provide timely solutions.

Expert Technicians:

After-sales service will be carried out by our team of skilled and experienced technicians who are well-versed in the installation, maintenance, and repair of cargo lifts. They have the necessary knowledge and expertise to handle any issues that may arise.

Spare Parts Availability:

Our after-sales service includes genuine spare parts inventory for machines. This ensures that any faulty components can be replaced in a timely manner, minimising downtime and ensuring smooth operation of the lift.

Training and Education:

After-sales service may also involve providing training and educational resources to customers. This can help you understand the proper usage, maintenance, and troubleshooting techniques for the cargo lift, empowering them to handle minor issues themselves.

Warranty Coverage:

We provide 5 years warranty for the main structure of cargo lift, and one year warranty for the spare parts. This ensures that customers are protected against any manufacturing defects or malfunctions during the warranty period, providing them with peace of mind.

A Comprehensive Guide to Choose and Buy Cargo Lifts

1.Load Capacity: Determine the weight and size of the cargo you need to transport and choose a proper liftplatform with a capacity that can accommodate it. At MORN LIFT, we provide custom material handling lift equipment that can load up to 50 tons.

2. Platform Size: Consider the size and dimensions of the lift and ensure it can fit in your space and accommodate the size of the cargo you need to transport. Just a photo of your lift installation site plus the dimension of it, we could recommend a precise platform size for you.

3. Lifting Height: Calculate the height between the floors in which you plan to transport goods. Confirm both the lifting height and installation height.No matter you plan to install the cargo lift in warehouse, factory or workshop, we can help confirm the best lifting height for each site.

4. Lifting Speed: Determine how quickly you need to move the cargo and choose a lift with a speed that can meet your requirements. Faster is not always better. A safe lifting speed is the first point we should consider.

5. Power Source: Choose a lift that is powered by a source that is appropriate for your facility, such as electricity or hydraulic power.MORN LIFT cargo lift equipment is mostly powered by hydraulic systems which are powerful enough to load heavy-duty materials.

6. Safety Features: Look for lifts with safety features such as emergency stop buttons, safety gates, and sensors that can prevent accidents and ensure safe transport of goods.Cargo lift safety is the key factor both the user and the cargo lift manufacturer care. Hence our cargo lifts are configured with complete safety devices to ensure work safety.

Customer Feedback

MORN goods lifts, cargo lifts, residential freight lifts, material lifts are widely installed in warehouses, storehouses, factories, workshops, logistics centers, restaurants, retail stores etc. Here are some feedback photos from our customers.

3D Design Samples

Cargo Lift FAQ

A cargo lift is extremely useful for the delivery of goods on different floors. After assembling the machine; the customer should do a couple of load tests to ensure it is working properly.

Before that, please kindly check if the voltage of power supply is the same with the power unit of your lift. If not, please use one voltage converter to adjust or contact the manufacturer directly.

Secondly, please ensure the hydraulic pipe is connected well with cylinders and oil box. If any oil leakage, replace the pipe or tighten the nut firmly.

Third, please check all oil lines are in good condition and make sure there is enough hydraulic oil in the power unit.

At first, the lift may rise or fall slowly. Please don’t worry! This is because of new cylinders and their parts.

All will be better after a short time. If you face any technical hitches, please do not hesitate to contact us. Our professional technical team will solve your queries immediately.

Hydraulic lifts are widely used in factories, warehouses, industrial plants, institutions—anywhere products or supplies need to be moved from one level to the other.

Guide rail lift provides fast, efficient, convenient and safe access to mezzanines, balconies, basements, and any levels in the multi-storied building. The freight elevator can be installed indoor and outdoor.

Hydraulic goods elevator not only have all safety devices of the traditional lift but also have the following unique system:

1. Spillover valve: it prevents high pressure when the machine moves up.

2. Manual emergency valve: it can go down to the nearest floor and open the door in case of any emergency.

3. Manual pump: it can go down to the nearest floor and open the door in case of any accident.

4. Pipe fracture valve: when the hydraulic system pipe breaks, it can cut down the channel of the oil to stop the falling.

Even though it is widely used in modern construction, it has a huge size and is so heavy that its safety performance requirements are very high in the construction. General requirements for safety rope fall under the following three areas.

1. Replacing the wire rope: damaged wire rope should be replaced to prevent accidents.

-Truncation bit off both sides of the rope should be knotted securely to prevent after cutting loose strands.

2. Do not overload the lift: there should be overload limiter or torque limiter installed. It should also be installed from the ceiling position to prevent excessive volume to pull off the rope.

3. The new rope should be replaced with the same type and size of the original installation of the rope.

If you use a different type, ensure that the new rope is not less than the old rope performance, and can match with the drum and pulley groove.

Rope twist should be consistent with the direction of the spiral groove rope reel. Single winding rope guide should be set up to prevent chaos rope.

Cargo elevator is widely used in a warehouse. Many suppliers will receive tons of requests from customers, so, how to make a good cargo elevator?

Some suggestions are as follows.

1. A good cargo elevator has an emergency decline. If an operator encounters an emergency, can he or she make the cargo lift go down by a certain button?

2. Chain model: the chain model of a good cargo lift will change according to the cargo elevator, load capacity, and lift height.

3. Interlock: if the platform door is open, the elevator will stop working.

4. Hydraulic cylinder: it should have an anti-explosion valve in the cylinder. If the oil tube has a breakage, the valve will block the oil.

5. If the cargo elevator is installed outdoors, the painting should be of high quality that can last.

Cargo lifts are widely used in most warehouses. The main cargo lift includes stationary Scissor lift and lead rail lift. It is important to note that the lead rail lift does not need depth pit, and it is highly popular than the scissor cargo lift.

The lead rail cargo lift has three kinds of installation. One is installed on the ground, and the ramp is added for easy loading and unloading cargoes. The other installation is fixed on the ground directly.

The last is pit installation. Our customer has the freedom to choose a suitable cargo lift according to his or her needs.

Best of all, the lead rail lift is frequently purchased by a dozen of clients since 2014. This is because the product is of good quality.

It is meticulously painted, durable, safe to use for your needs. Also, the lead rail lift is highly dependable because of its incredible service to most of the customers. The machine is affordable for everyone.

1.Before operating a cargo lift, kindly check the following:safety rope, hydraulic oil pipe, electric connection, limit switch, emergency stop. Also, confirm if the elevator is working and finally operate it.

2.Goods to be transported should be in the center of the cargo lift, and should not exceed lift’s platform. The platform door of a cargo lift prevents the goods from being thrown out during lifting up and down.

3.Only a professional worker should operate the cargo lift.

4.If you get into some mechanical problems, immediately stop operating the cargo lift. The mechanical problems include the following:

A. Goods lift for sale not lifting up or down.

B. Cargo lifts lifting up and down with intense vibration and noise.

C. Any other person operating the lift should be alert in case of these emergencies.

Optional suggestion

- Add the overload warning.

- Include a mesh cover for Cargo lift

- Include anti-fall device which will prevent cargo slipping.

- Have a platform guide rail door with interlock.

The vertical cargo lift is an excellent machine for you, we produce according to our customer needs, like platform size, load capacity, and lifting height.

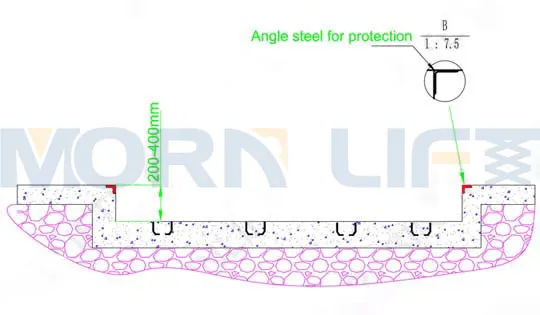

There are two installation ways for a vertical cargo lift. Directly install on the ground and fix in a pit. Normally the depth of a pit should be 20mm. You could correctly install the lift.

The cargo lift can be fixed on the ground floor or into one pit. If it’s on the ground floor, the user is recommended to prepare one ramp to move freely. One pit prepared will be better, which enables the work platform to be in level with the ground. Absolutely no ramp needed.

To prepare one pit, below are some of the advice for your reference:

Foundation:

1. Pouring concrete (C30) should be 400mm in depth.

2. Embedded angle made of steel should be 50 by 50 by 5mm to ground the foundation.

3. The embedded conduit between power supply and foundation should be determined keenly.

Remarks:

Pit size: This item is based on the user’s request for platform size.

1. Ensure the platform level is okay when concreting.

2. The size of the hole should be kept straight with the ground hole being vertical.

3. Size of the embedded part should be 1600 by 400 by 14 in millimeters.

4. Put the entrenched part into foundation when concreting, at the side of the lead rail for fixation.

5. Keep the foundation dry; if wet or water comes in accidentally, please make one drainage pipe.