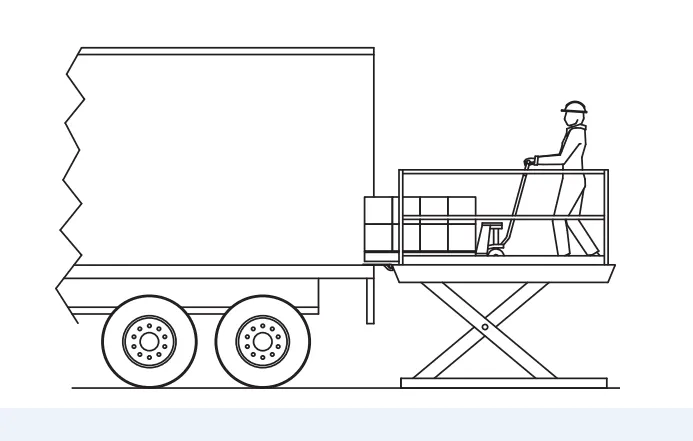

The vertical cargo lift uses hydraulic cylinders to lift up, chains and wire ropes to pull the workbench. After it is raised to the target height, it is automatically leveled with the floor through a limit switch. A limit limit switch is installed on the structure of the guide rail elevator to prevent the failure of the leveling limit switch and the guide rail elevator continues to lift and cause dangerous accidents.

Table of Contents

Vertical cargo lift-Before use

- The vertical cargo lift has been inspected and debugged before leaving the factory, and all technical indicators have reached the design requirements. The user only needs to read this manual carefully and strictly follow the steps when using it.

2.Non-professionals are not allowed to adjust the hydraulic system, electrical control system and platform structural components.

3.When the platform is installed and used for the first time, carefully check whether there are any abnormalities in the hydraulic pressure, electrical appliances, and structural components. Only when there is no abnormality can be debugged, and the load test should be performed after 3 to 5 times of no-load. This step also applies after the platform overhaul.

4.The platform has a guiding structure, carefully check the guiding structure and make sure that the guiding structure is good before debugging. The platform must not be loaded during debugging.

Vertical cargo lift-Operation

1.The operation of the vertical cargo lift is designed as a fully automatic operation mode, and the corresponding action can be realized by pressing the corresponding button on the control box, and it will automatically stop after reaching the working height. The realization of these functions is realized by electrical appliances such as AC contactors and limit switches.

2.If the operator is replaced, the new operator should carefully study the operating experience of the former operator and read the manual carefully. The load should be placed in the center of the workbench and overloaded strictly.

Vertical cargo lift-Matters needing attention

If possible, a dedicated platform operator should be provided. What the operator should observe when pressing the button:

1.Whether the load is placed in the center of the guide rail type lifting platform, otherwise the relevant personnel should be urged to adjust.

2.After pressing the button, whether the guide rail lifting platform has corresponding action, otherwise, press the “stop” button immediately to check whether the power line is lack of phase to avoid burning the motor.

3.What the operator should observe during the lifting process of the guide rail lifting platform:

(1). Observe whether there is oil leakage or oil leakage in the hydraulic oil circuit.

(2). Whether there is abnormal noise in each rotating part. Deal with it accordingly. Replace severely worn parts in time.

(3). Whether the hydraulic pump has abnormal noise. If so, it should be dealt with in time.

Vertical cargo lift-Maintance after one year operation

1.Clean the hydraulic pump, replace the shaft pin and other parts of the rotating and transmission parts that are severely worn.

2.Add sufficient lubricating oil to the rotation and transmission parts, and check whether all the fasteners of the rail-type lifting platform are loose.

3.Check the wear of the top rod of the cylinder, check whether the control circuit and electrical appliances are corroded and rusted, and whether the joints of the circuit are loose, collapsed, rusted, etc. Find problems and deal with them in time.

4.Whether the steel structure of the guide rail lifting platform is corroded or rusted, clean it up in time, spray paint, and check all the fasteners of the hydraulic oil circuit.

Vertical cargo lift-hydraulic oil replacement

Hydraulic oil is the power transmission carrier. It is very important to maintain the viscosity and cleanliness of the hydraulic oil. Replace the hydraulic oil at least once every six months. If the frequency of use is high, more than 10 times a day, replace the hydraulic oil once every 3 months. Use 46# hydraulic oil in winter and 32# hydraulic oil in summer.